This test, indispensable for measuring the capability of an engine to hold pressure, is an integral part of any thorough engine health assessment due to its ability to pinpoint issues that rob you of power and reliability. But, a cylinder leak down test, takes it to the next level and measures, cylinder pressure loss. What is a leak down test

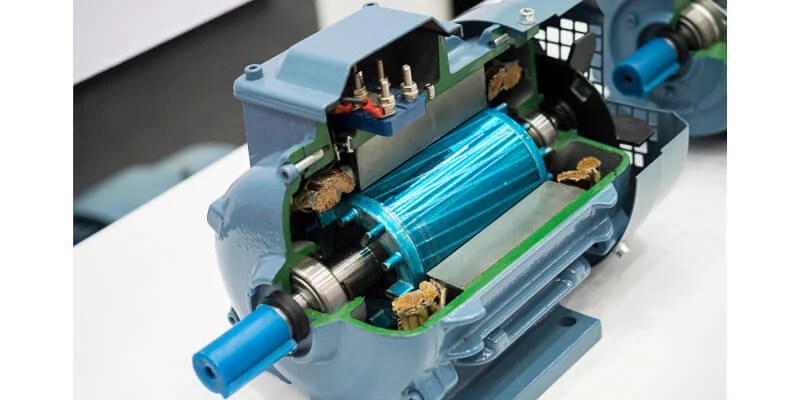

Three-Phase Induction Motor Operation Explained - Technical Articles

A leak down test is a method of using compressed air and a specialized gauge set that reads differential pressure to evaluate the condition of an engine’s cylinders, pistons and rings, and valves and seats without disassembling the engine.

This test allows me to go beyond the numbers and diagnose the root cause—whether it’s worn piston rings, a burned or sticking valve, or a failing head gasket

A cylinder leak down test helps me assess internal engine health, isolate failing cylinders, and determine whether an engine needs a simple fix or a full rebuild. The first step is to make sure the engine is at (or very near) top dead center on the compression stroke This will ensure that both valves are closed and the cylinder is in it’s most airtight configuration A cylinder leak down test or cylinder leakage test, is actually similar to a compression test

So, a compression test measures, how well your engine’s cylinders are sealing