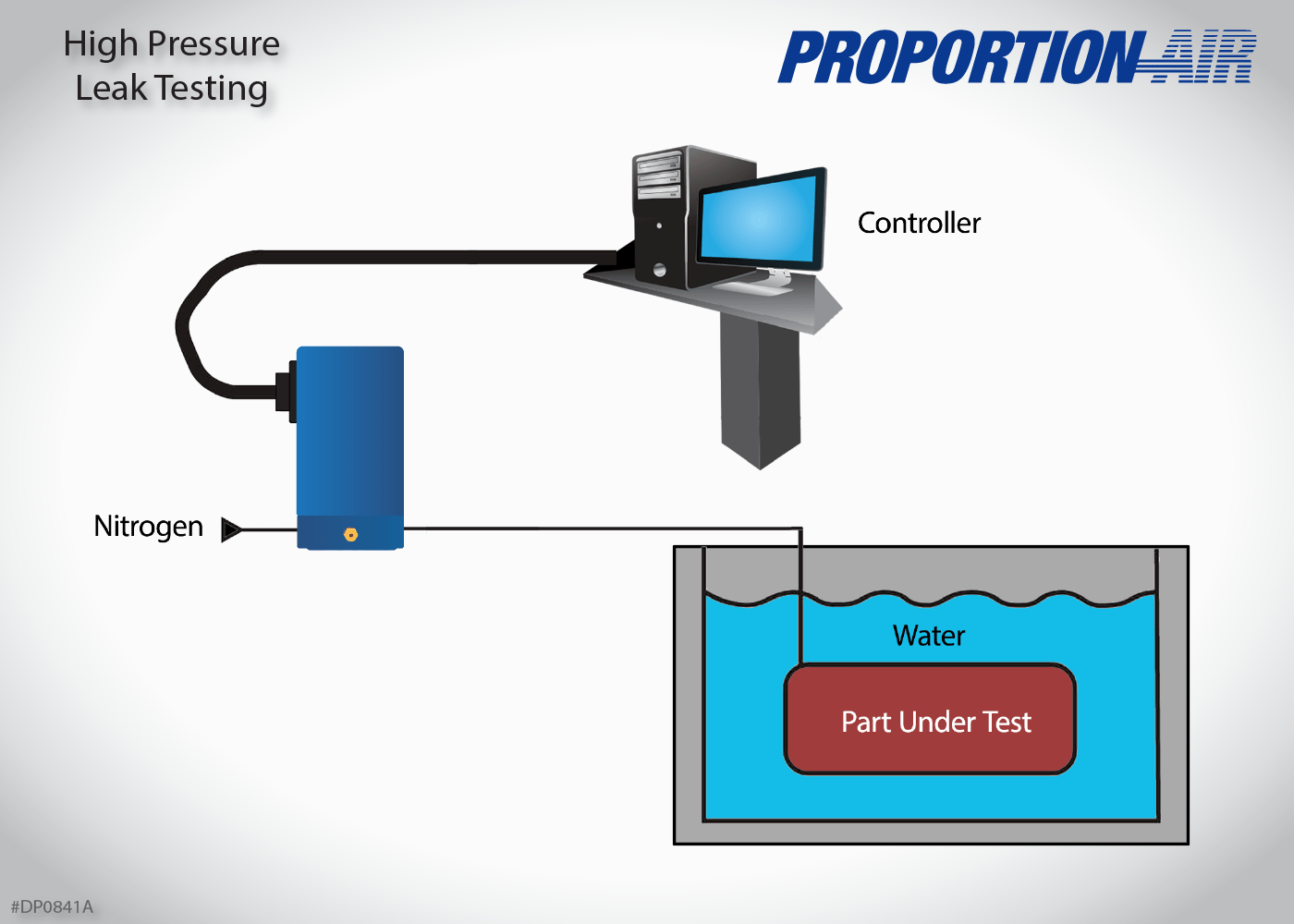

During the test, a part is pressurized, and the pressure is monitored over a specific time period Discover the importance of a leak check in maintaining system integrity and preventing costly repairs If the pressure drops below a predetermined threshold during the test, the part is deemed to have a leak and is rejected

Pressure Decay Leak Testing of Valves

A detailed guide to asme b31.3 pressure leak tests, exploring methods, guidelines, and procedures for safe and effective piping system testing.

Pressure testing involves simulating the flow of water through your pipes and checking for leaks under high pressure

In this blog post, we’ll show you how to pressure test plumbing for leaks using simple tools and techniques that any diyer can master. In simple terms, the pressure decay test fills a pressure vessel with air until it reaches its target pressure, cuts the air source to isolate the pressure, and measures the decay (loss) of that pressure over a set period of time A pressure loss greater than a predetermined setting indicates a leak The sensitivity and accuracy of the pressure decay measurement is a function of the test part.

Pressure decay leak testing is a reliable method for detecting leaks in sealed systems By monitoring pressure changes over time, even small leaks can be identified, helping manufacturers maintain product quality and safety Pressure decay testing arrangement pressure decay is probably the most widely used method of leak testing in manufacturing production lines The process is uncomplicated, relatively inexpensive and easily automated.